Every container begins its life at a manufacturing plant. These facilities design and produce containers tailored for durability, security, and ease of handling. The main material in container construction is steel. Steel sheets are cut, pressed, and welded to create the standardized units recognized worldwide.

Every container begins its life at a manufacturing plant. These facilities design and produce containers tailored for durability, security, and ease of handling. The main material in container construction is steel. Steel sheets are cut, pressed, and welded to create the standardized units recognized worldwide.

Upon completion, new containers undergo a series of rigorous inspections and tests. These quality checks ensure they can withstand harsh maritime environments while protecting the goods inside. Tests include verifying structural integrity, water tightness, and lock functionality. Containers must adhere to standards set by the International Organization for Standardization (ISO) to ensure uniformity and compatibility.

Once containers pass inspection, they’re transported to depots where they’re prepared for service. Labels, unique identifying numbers, and company logos are affixed. RFID tags and GPS tracking devices are added for monitoring locations and movements throughout the shipping process.

Booking and Planning Shipping Logistics

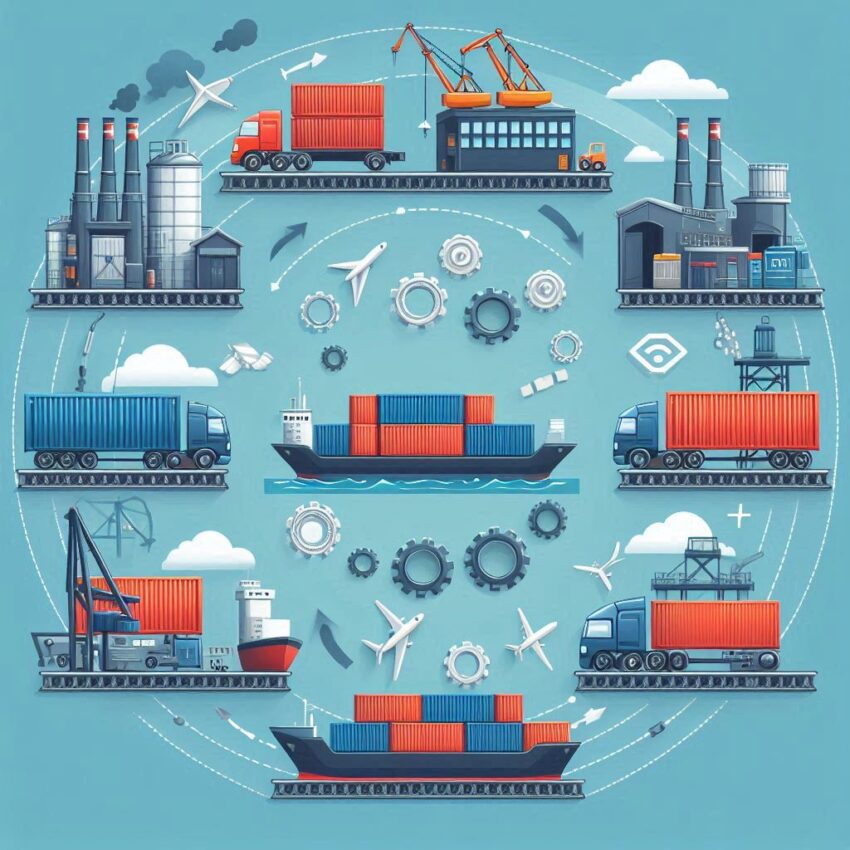

Shippers coordinate with logistics companies to arrange the transport of goods. This stage involves meticulous planning to ensure an efficient journey.

Paperwork and compliance checks are necessary before a container can be loaded. Documentation includes bills of lading, customs declarations, and packing lists. Compliance ensures that contents are safe and legal to ship.

Containers may be transported via trucks, trains, or barges to reach ports. Each mode offers varying advantages based on distance, speed, and cost. Supply chain management teams assess the best routes and options.

Loading at the Port

At the port, containers are loaded onto ships using cranes. Ships often have a specific stowage plan to maximize space while maintaining stability. The container shipping journey is now ready to commence.

Maritime Transportation

Once on board, containers embark on the maritime leg of their journey. Key players in this phase include shipping lines, port authorities, and maritime insurers.

Containers must endure rough conditions including waves, saltwater, and temperature fluctuations. Ocean liners are capable of carrying thousands of containers. Throughout the journey, constant monitoring ensures containers remain secure, and unexpected issues are managed promptly.

Upon reaching the destination port, containers are offloaded via cranes and transported to holding areas within the port. This process involves coordination among ship crews, port workers, and customs officials.

Customs Clearance and Inspection

Customs clearance is a critical phase. Containers are inspected to ensure contents match declarations. Authorities may inspect randomly selected containers or those flagged for discrepancies. Once cleared, containers are ready for the next leg of their journey.

Inland Transportation

After clearance, containers begin the inland transportation leg. Containers are moved by truck, train, or barge, based on the destination’s proximity and available infrastructure.

Last mile logistics refers to the final phase of delivering containers to end destinations. Efficiency here impacts delivery times and overall customer satisfaction. This stage poses various challenges such as traffic congestion, local regulations, and scheduling intricacies.

Unloading at Final Destination

Unloading at the final destination marks the culmination of the cargo’s journey a critical phase in the logistics and chain process. When containers reach their designated delivery points, the first step involves careful unloading, typically carried out with specialized equipment such as cranes, forklifts, or pallet jacks, depending on the nature and size of the cargo. This unloading process needs to be meticulously managed to prevent any damage to the goods.

Once unloaded, contents are diligently checked against the manifest documents to ensure every item is accounted for. This step is crucial to verify the accuracy and completeness of the shipment, which helps prevent discrepancies, losses, or misdeliveries. The manifest acts as a detailed inventory list that includes descriptions, quantities, and other pertinent details about the cargo.

In some cases, goods may undergo further inspection upon arrival. This additional scrutiny can be necessitated by various factors, including customs regulations, quality control protocols, or safety standards. For instance, perishable items might need to be examined for freshness, while high-value or sensitive goods could be checked for integrity and security.

After passing these checks, the items are then prepared for their next phase, whether that be immediate distribution or storage. Distribution involves organizing the goods for delivery to various end-users, retailers, or other downstream recipients, ensuring they reach their final point of efficiently. Alternatively, if the goods are destined for storage, they are transported to warehouses where they are stowed appropriately, awaiting future dispatch.

Return of the Empty Container

Once emptied, containers don’t rest long. They’re promptly sent back to depots for cleaning, repairs, and preparation for reuse. Efficient turnaround is crucial for maintaining the flow within the global supply chain.

Challenges in Container Shipping

Containers must face harsh environmental conditions ranging from scorching heat to freezing temperatures, and from dry desert climates to humid tropical weather.

Ensuring the security of containers against theft, tampering, or unauthorized access is fundamental. RFID tags, GPS trackers, and seals help in monitoring and safeguarding containers.

Navigating through various international regulations can be challenging. Meeting all regulatory requirements involves coordination among shipping lines, logistics providers, and customs officials.

Modern shipping relies heavily on technological advancements. Integration of software solutions for tracking, inventory management, and automated documentation streamlines the shipping process.

Balancing cost efficiency while maintaining service quality remains an ongoing challenge. Logistics providers constantly seek ways to optimize routes, reduce fuel consumption, and lower operational costs.

Technologies Shaping Container Shipping

Automation in ports and warehouses, such as automated guided vehicles (AGVs) and robotic cranes, significantly improve efficiency and precision in handling containers.

The Internet of Things (IoT) enables advanced tracking systems. Sensors monitor various factors such as temperature, humidity, and GPS locations, facilitating better management and quicker response to issues.

Blockchain technology enhances transparency and security in shipping logistics. By providing an immutable ledger that records all transactions and movements, blockchain builds trust and reduces fraud and errors.

Big data analytics enables supply chain management teams to gain valuable insights, predict trends, and optimize routes. It helps in decision-making processes and improving overall operational efficiency.